Products

Air shaft specialist.

Air shaft specialist.

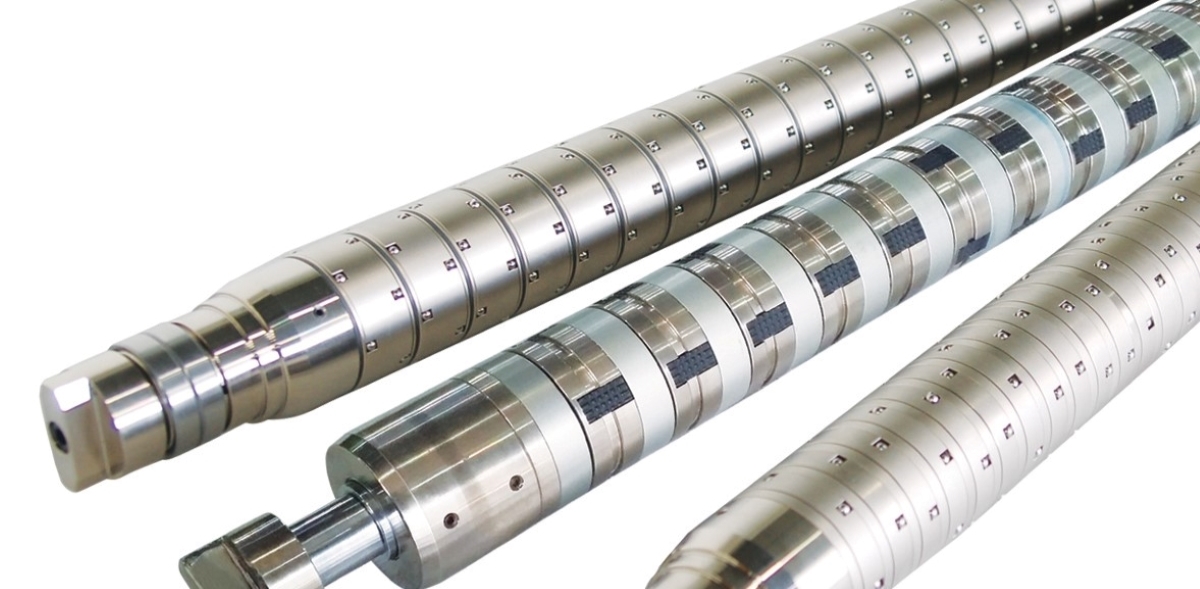

| SF-1100 | The SF-1100 type air shaft is the most common product in the areas of windings and rewindings. It is usually used for a minimum/maximum viewing range of 38 to 500, and special specifications can be made. |

|---|---|

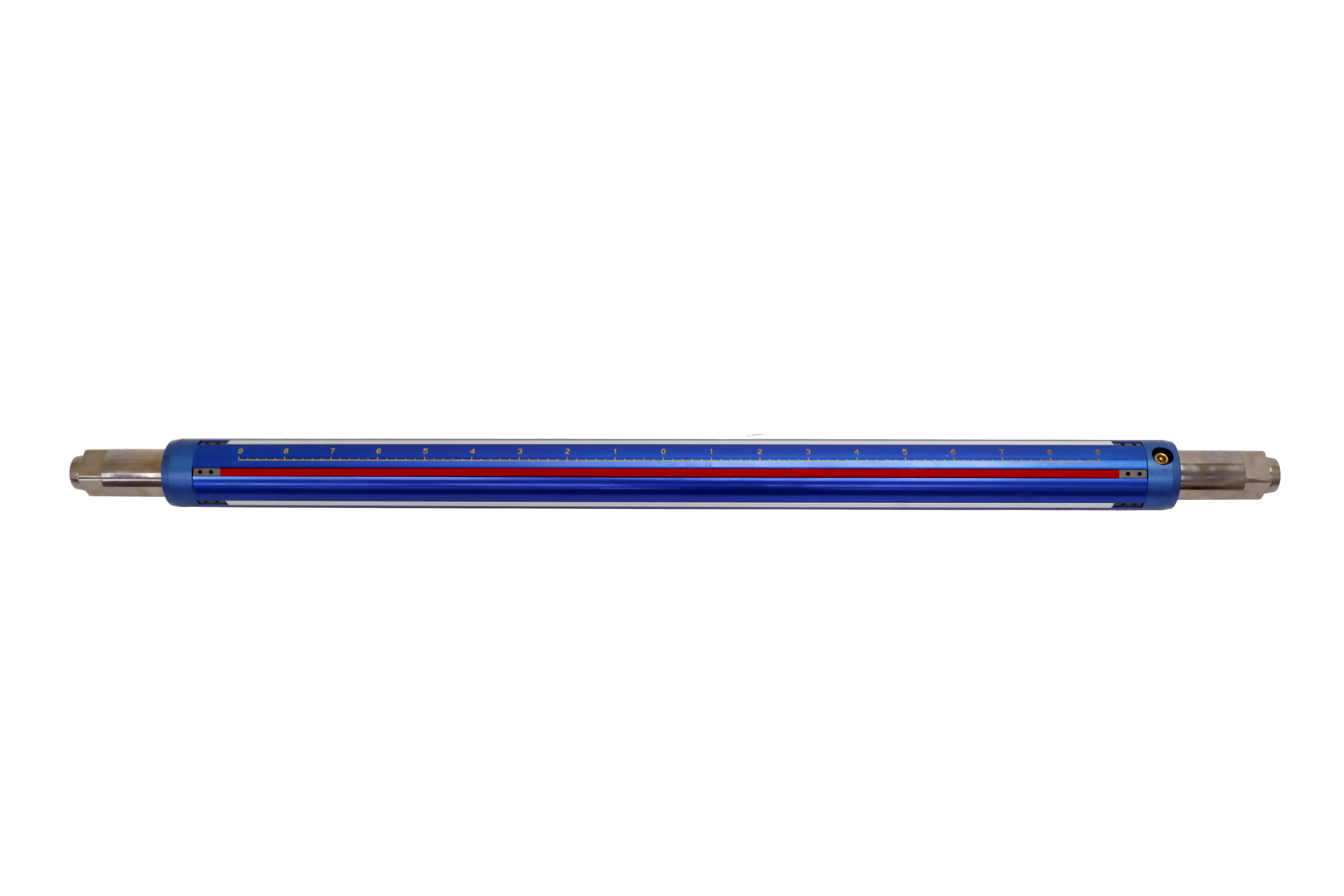

| SF-1200 | The advantage is that the body material of the shaft is lightweight with aluminum. It is usually used for a minimum/maximum viewing range of 38 to 500, and special specifications can be made. |

|---|---|

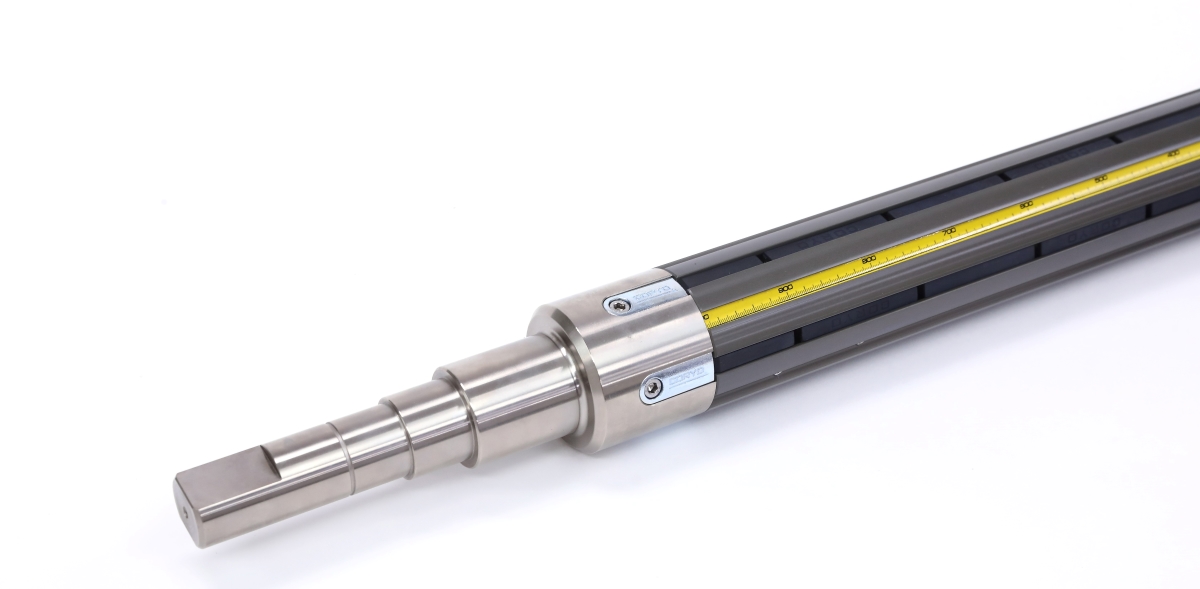

| SF-1300 | CFRP TYPE uses carbon fiber pipes to maximize light weight. It's also elastic and durable. |

|---|---|

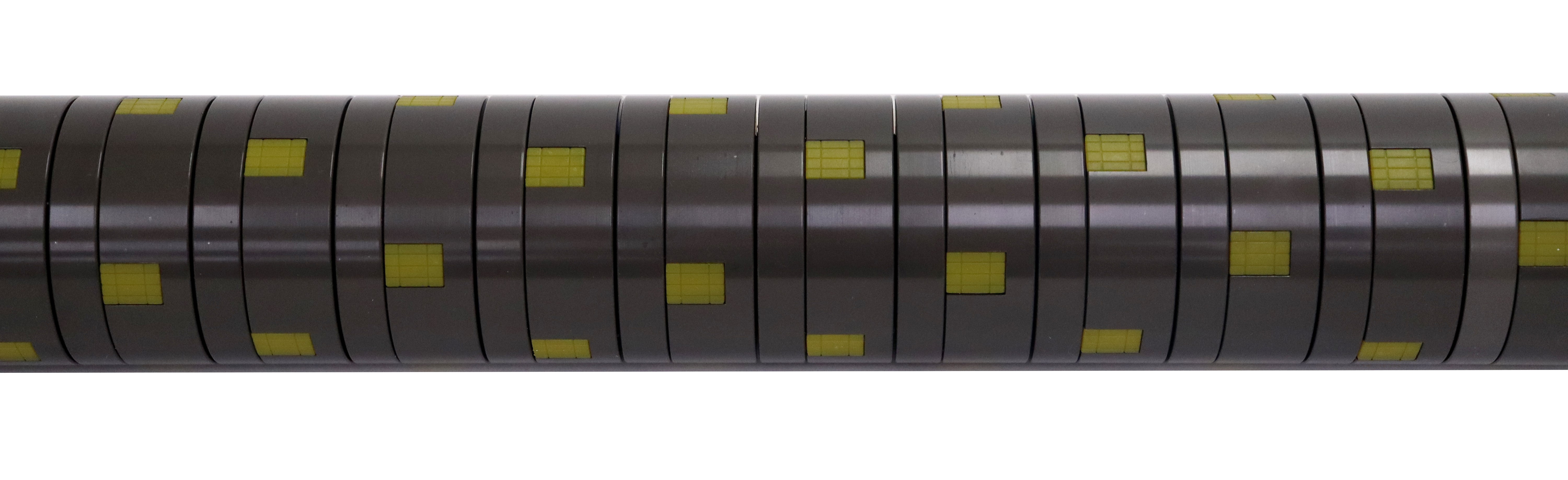

| SF-2100 | The area where the core is chucked is made of rubber, so it does not deform the core, and it is a product with excellent authenticity and epicenter. |

|---|---|

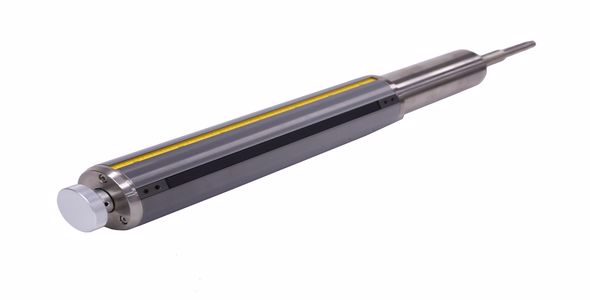

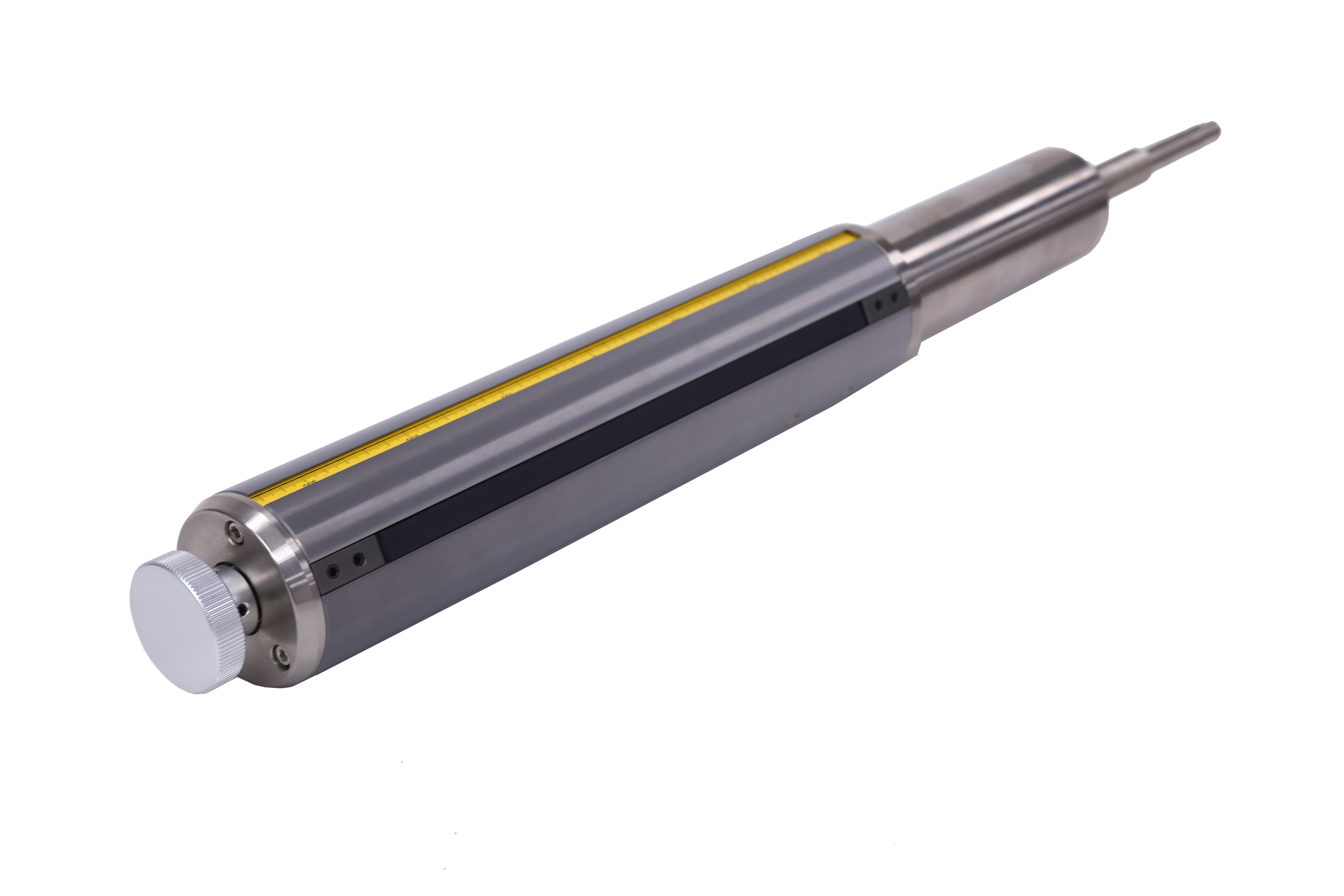

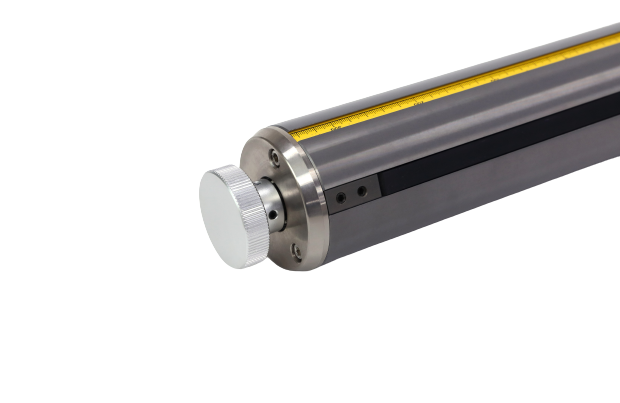

| SF-2200 | It's the same specification as number 2100. The adjustable handle at the end of the shaft allows changing the shaft position during operation. |

| SF-2200 | It's the same specification as number 2100. The adjustable handle at the end of the shaft allows changing the shaft position during operation. |

|---|---|

| SF-2300 | The centering shaft is suitable for high speed and precision requirements. The air is injected sequentially to chuck the core for excellent precision. Precision slitting and seismic intensity are appropriate for the desired operation. The lugs are divided into six parts, each of which has three rows of air chucking inside the core in sequential motion. It is developed to maintain the highest level of seismic intensity even when the core internal diameter is not constant. |

|---|---|

| SF-2400 | More than 6" can be produced. Ultra lightweight improves worker convenience and reduces risk of injury. The RUBBER LUG operates individually, allowing operation to continue even if one LEAK occurs. Insert when working on expensive film. For easy attachment, you can choose the ball roller insertion option. |

|---|---|

| SF-6100 | The URETHAN AIR TUBE expands in all directions to 360 degrees for excellent core chucking. Therefore, it is a product with excellent concentration and epicenter. You can optionally select the ball roller for easy attachment. |

|---|---|

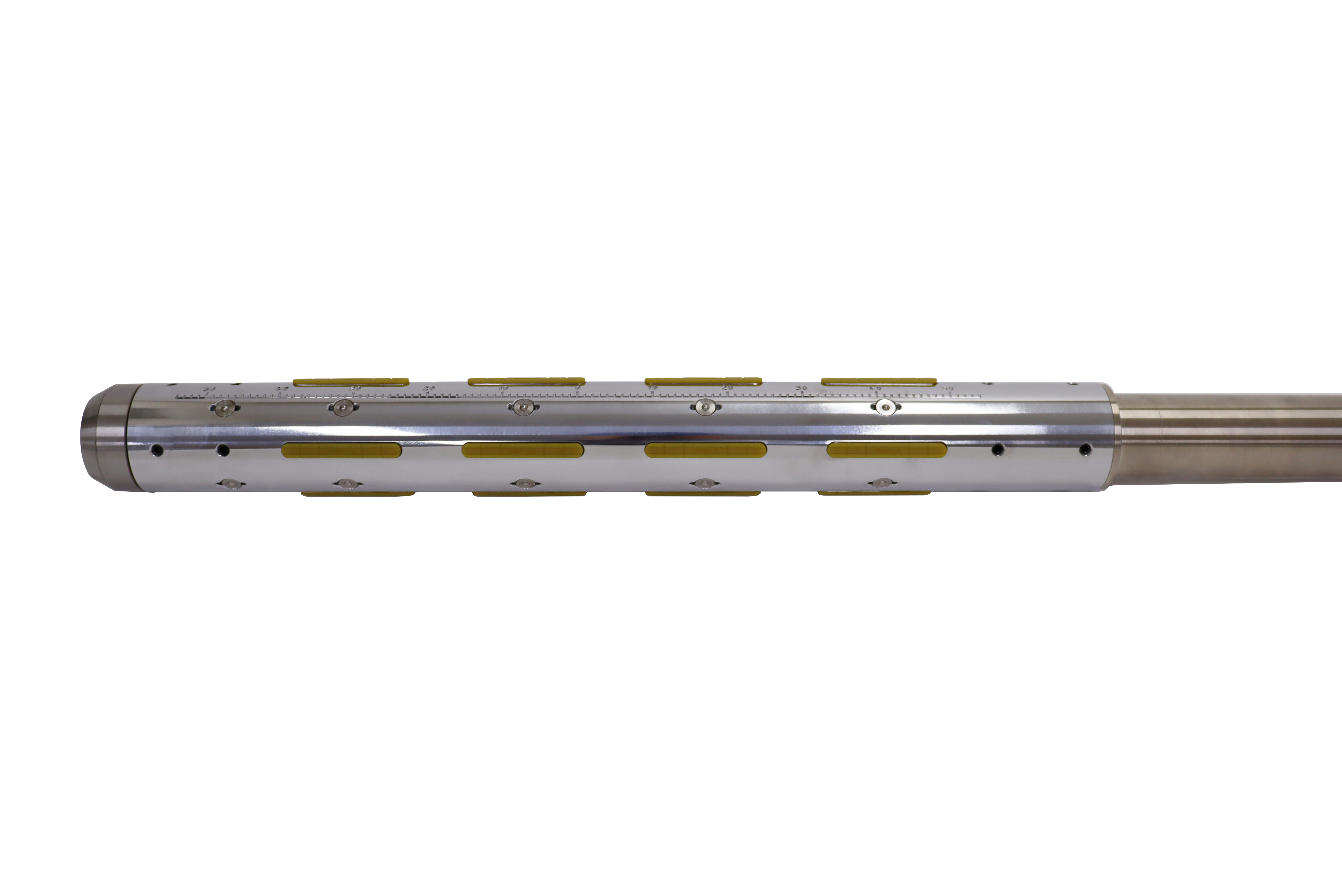

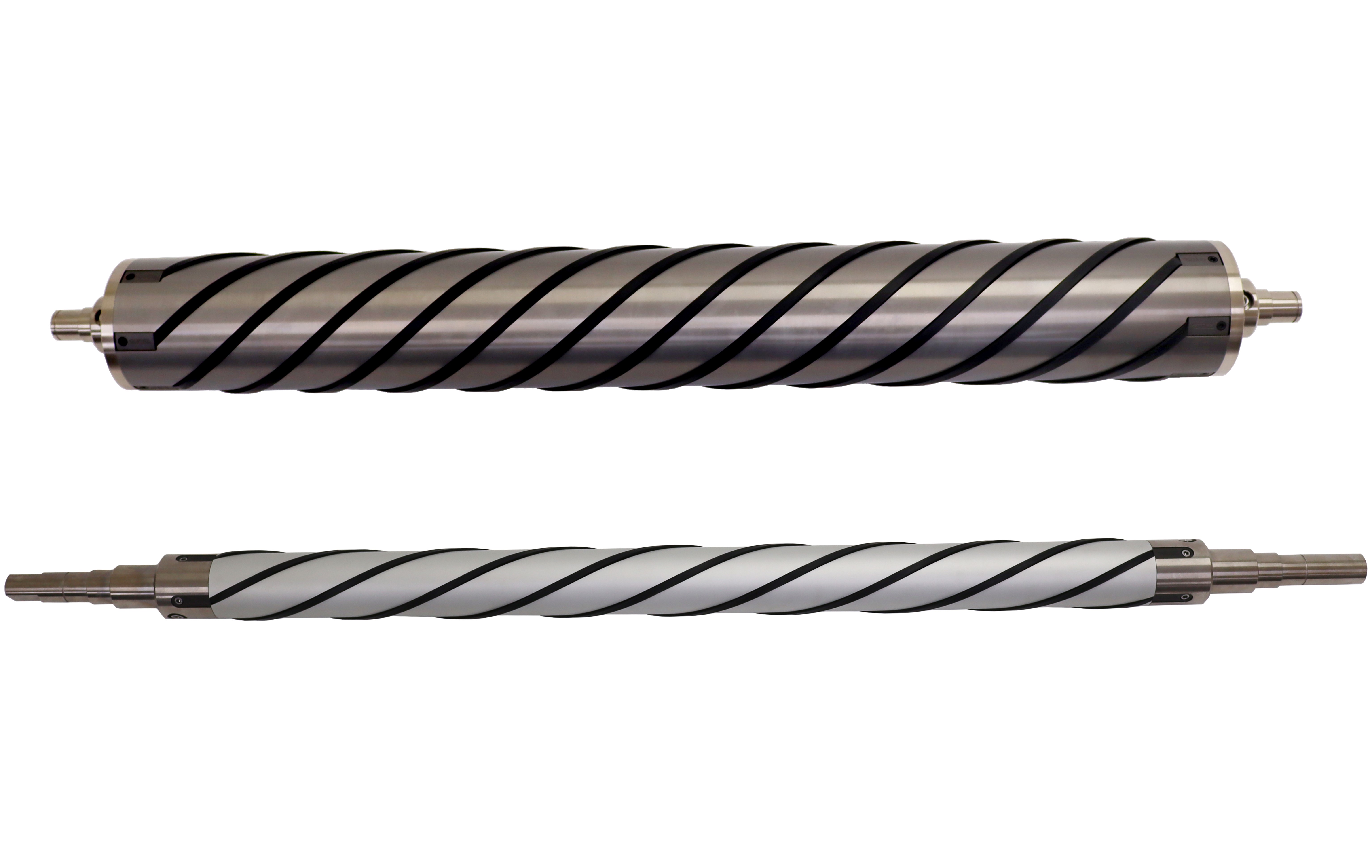

| SF-5100 | Mechanical shafts can be made of two types: mechanical/ mechanical/air-free construction and air supply mix. It is a structure that grips the core by operating a lug using a handle and an impact wrench. The air mechanical system operates the cylinders inside the shaft via air supply. At this point, operate the lug under pressure from the cylinder to grip the core. You can also make reverse type air mechanical. Additionally, urethane lining process can be added to the lug surface to increase ball roller / grip strength to facilitate core attachment. |

|---|---|

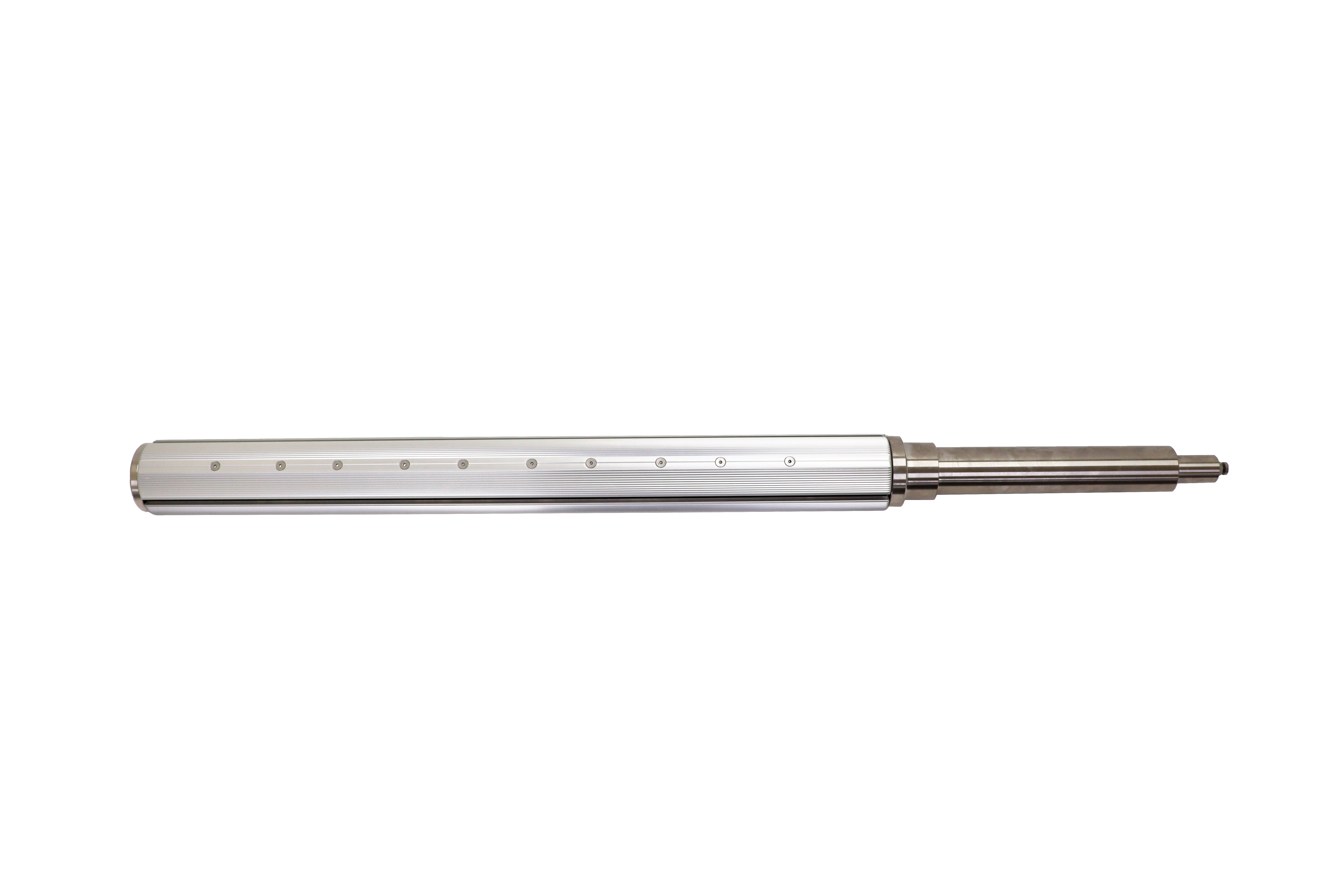

| SF-3100 | The cover attached to the shaft exterior expands to extend the inside of the core as a whole. Therefore, it is possible to minimize deformation. |

|---|---|

| SF-4100 | The Air Friction shaft is a uniform pneumatic pressure injected into each joint on the central axis to adjust the amount of core slip, allowing uniform torques to be maintained during slitting rewinding. Add urethane lining lugs to the aluminum body to prevent slip. |

|---|---|

| SF-4600 | The ball protrudes to precisely chuck the inside of the core. Therefore, it is possible to maintain the best seismic intensity. The pressure of the air controls the praction and the uniform rotational force of the bearings. |

|---|---|

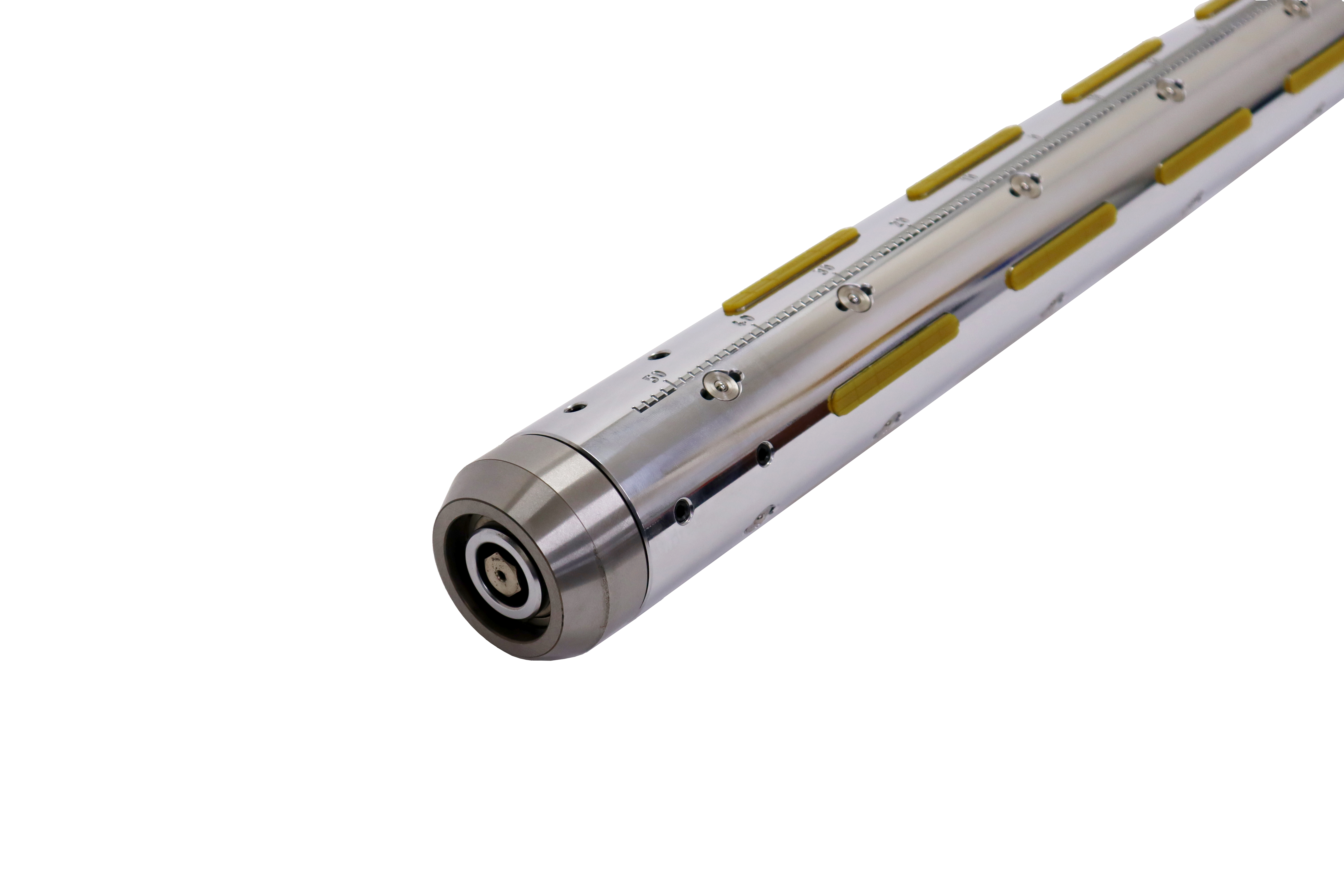

| SF-4700 | An additional bearing is inserted inside the chucking ring to maintain the highest precision. The ball protrudes to precisely chuck the inside of the core. Therefore, it is possible to maintain the best seismic intensity, and the rotational force of the bearing achieves the highest precision. The pressure of the air controls the prraction and the uniform rotational force of the bearings. |

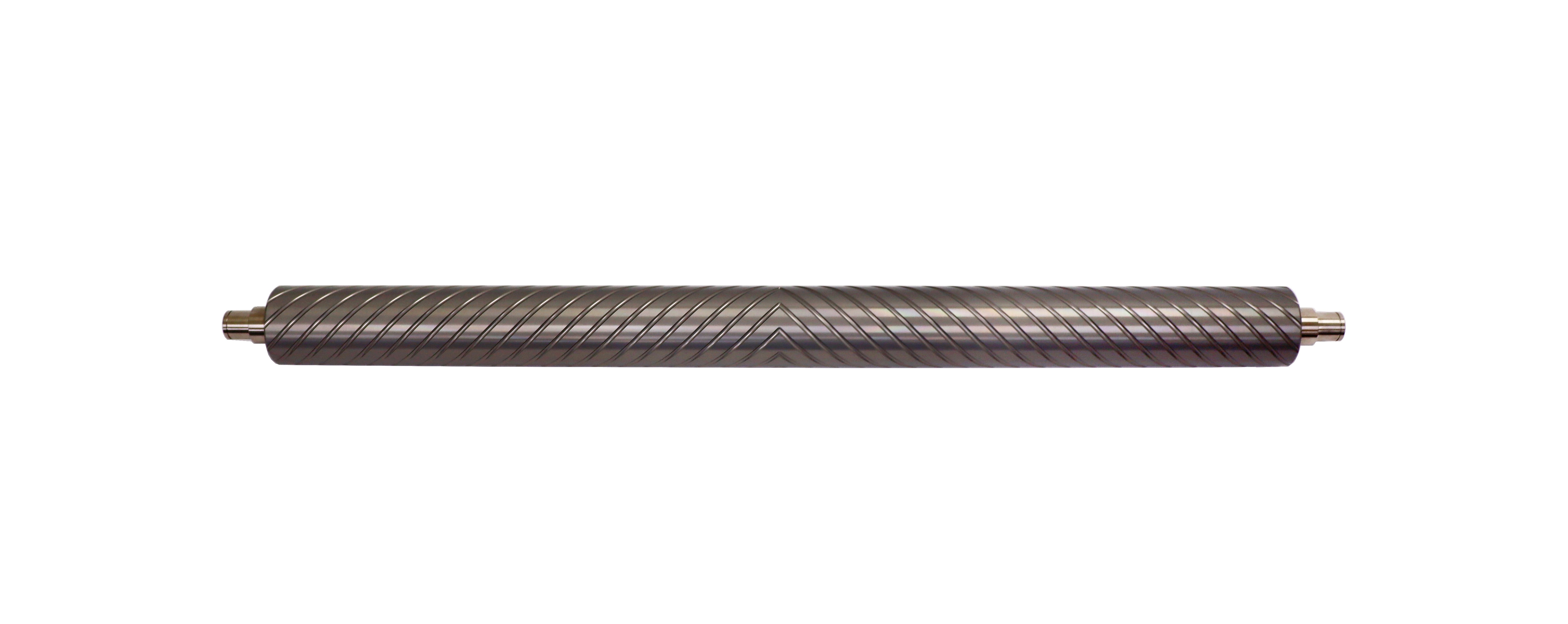

| SF-7100 | Spiral type is a spiral structure that chucks the inside of the core to maintain the highest level of seismic intensity and precision. Perfect for Slitting and Unwinding / Rewinding operations requiring the highest precision. For easy attachment, you can choose the ball roller insertion option. |

|---|---|

| SF-ROLLER | Used to expand the web by eliminating wrinkles. |

|---|---|